That being said, this is either going to be my greatest refinishing project ever OR it could end up being the worst! So I thought it would be fun to document my adventure as each step happens . . . no matter how much a success or mistake each step is!

My husband purchased me a treadle sewing machine as an anniversary present last weekend! Being as thrifty as he knew I would want him to be he found me a fixer upper. It is a White Treadle and it is beautiful . . . or at least it was beautiful at some point in time! :)

Really I do find it beautiful even if it is in beat up condition! But as I looked closely at it I knew there would be a lot of work to do to really make this piece shine. It sat for the week and most of the weekend . . . yes, I wasted this beautiful 70 degree weekend. I complained all summer about it being too hot for re-finishing projects and then I wasted the beginning of the weekend. In all fairness though, I was unwinding after all the craziness of the little man's birthday bash.

I finally began to tackle this beauty today though. I removed the sewing machine and then my husband and I lugged it back down the stairs and straight outside where I was able to begin cleaning it off. As I looked at it closer in the sunlight it became obvious that this poor machine had been neglected for a very long time. I am almost convinced that this was stored in a leaky garage or a very, very wet basement. But for kicks and giggles I really like to imagine that it was forgotten about in a barn somewhere.

It appears that most of the piece is covered in wood veneer, which with time and the poor conditions it must have been kept in has either began to warp terribly or is now crumbling off of the table.

This is how I can justify refinishing this piece. I sincerely believe this piece would have been put into the garbage or sold for parts if my husband hadn't bought it for me. I know it is not worth anything in the condition that it is in and since it is a personal item that I would never dream of re-selling I knew I wouldn't be hurting any value by re-finishing the project.

Here are some closer looks of the table:

Yep . . . that is bird poop on the table! YUM! And when I removed the sewing machine I found bird seed in underneath it. If you look closely you can see that this entire side of the table is missing it's wood veneer top. I think I may like the planks better than the veneer.

This is the other side which is covered with veneer. It has some wear and tear but is still holding up.

This is the center of the table. Lots of wear but again more solid than some of the other areas of the table.

This is the right front. Once again, some bird poop. You can also see that some of the finish has lifted away from the piece. I am hoping some wood glue may help hold it in place.

Center of the front. Again . . . a lot of wear on the wood veneer but I really don't want to refinish this part. Despite the twig detail having worn away I like that you can still make out the "WHITE" outline. Hoping to figure out a way to keep the veneer from completely falling apart.

Right side of the table with wear along top and bottom.

Left side is in the best shape, mostly worn on the bottom.

One of the drawers. This is the one in the worst shape. I may keep an eye out on ebay and craigslist to see if any one is selling any of these drawers. The drawers seem very brittle.

I decided to try re-finishing the top and just touching up problem areas around the sides. So today I carefully sanded away all of the finish (and bird poop) from the top of the table.

After the sanding.

This part of the table was in the best condition and it has an awesome yard stick engraved on one side (of course I managed to not get it into the picture). The only thing I did here was sand down the side of the back piece so that the table would come completely up into place. If you look at the original picture you can see one side of the table was sloped downward because wood was scraping and not allowing the whole table to pop into place.

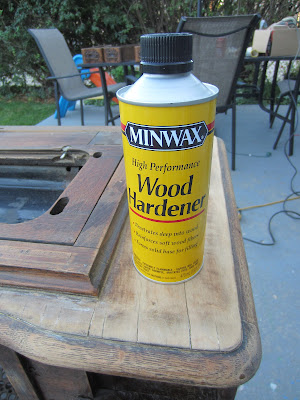

While I was at Menards on Saturday shopping for a matching stain for the table I stumbled upon this can of Wood Hardener from Minwax. I love their stain and figured I would give it a shot on this very old and weak table. I cleaned all the sand off of the table and let it dry a bit before applying. Then I applied the Wood Hardener wherever the wood was cracking . . . so basically just about everywhere.

It looked pretty once on but we will see how it all looks in the morning when all is dry. I am really hoping it will help to preserve this piece.

After all of this work I had run out of day light. So my final project was just to start cleaning up the treadle and the legs. I was amazed at the difference made just by using some dish soap and water and wiping dry immediately. It still needs a more thorough cleaning (I have to do some research on the best way to bring this part back to life) but I think the difference is already remarkable.

I am calling it quits for tonight but hoping that if the little one takes a good nap tomorrow that I can make a little more progress!

Pin It

Greetings from Sunny Florida,

ReplyDeleteI just purchased a very similar treadle and machine last weekend. There is no "White" on the drop front panel on my unit but it did have the twigs around the drawer pulls. This is a White Sit Strait treadle, which has the machine shifted to the right so that the operator is more in front of the needle. I have pulled the cabinet for future restoration and intend to make a simple top configured to fit a variety of sewing machines (Singer, White, New Home, Necchi).

White treadles are considered to be some of the best because of their great engineering. My treadle spins about 10 revolutions after a single press on the treadle.

White Rotary machines are also well thought of but sundries such as bobbins and bobbin cases are only available on the used market (Ebay). They do use 15x1 needles.

Have fun with your machine and your restoration.

Lee,

ReplyDeleteThank you so much for all the valuable information! I recognize you from the Treadle On group! I am always so appreciative of the information shared on these amazing machines.

I cannot wait to hear how your restoration goes as well!

Danielle